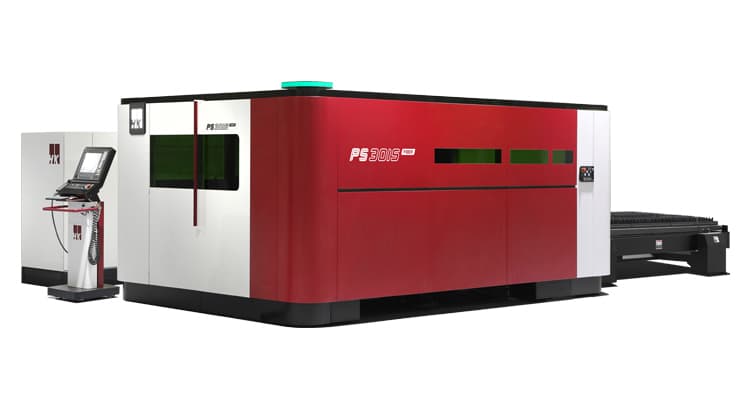

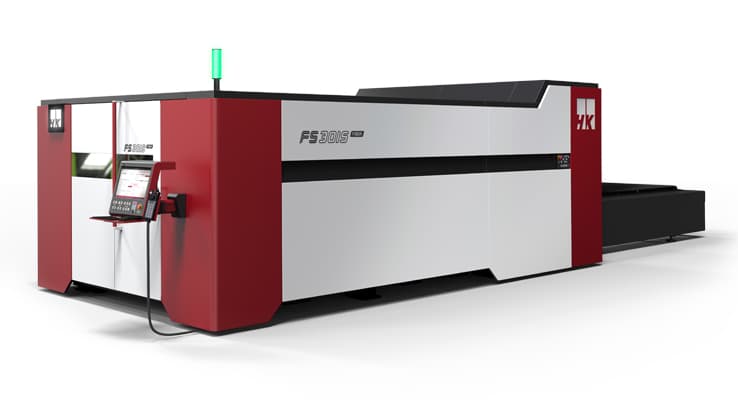

Fiber Laser Engraving Machine Cnc

Triumph's 30W desktop fiber laser can engrave on aluminum, gold, silver, steel, stainless steel, copper, and some plastic-like polymer for metal tools and machine parts.

This laser is a pulsed laser fiber laser with 1064 nm wavelength. It has a life expectancy of approximately 25,000 hours.